By the OS2O TEAM and our dear Oswaldo Rivera,

Down has an enormous capacity to trap warm air. Its low weight and volume and its high ability to compress and expand make it one of the most efficient materials for insulating garments.

In addition to the down’s capacity, measured in Fill Power, the quality of the down used in technical mountain clothing is certified through two criteria: the origin of the down and the composition of the filling.

Origin

As a raw material, down is a byproduct of the food industry. For this reason, one of the elements to be certified is that the down comes from farms with ethical treatment of animals. This certification must be issued at the place where the down is obtained. The China Feather and Down Industrial Association is responsible for control and certification in China. In Europe and the United States, the Responsible Down Standard (RDS) certificate provides this certification. OS2O products that use down from China have the Non-live plucking certificate, which means it has not been harvested from live animals. The hydrophobic DownTekTM down in our Nebulae 850 FP jacket has the RDS certificate. Companies like Re:DOWN®, with which OS2O collaborates, are at the forefront of the down recycling process, which is another element to consider regarding the origin of the down.

Composition

When we talk about downfilling, we refer to two elements: the down and the feathers. Both are used in the making of insulating garments. The down is responsible for trapping warm air, while the feathers provide structure to the filling panels in the garments. To make high-performance products, both elements need to be combined. It is not functional to have a product made entirely of down or only of feathers.

The quality in the composition of the down is defined by the percentage of down it contains and follows the guidelines of the IDLF, an international body that brings together all certification systems, establishing the minimum percentages.

At OS2O, we use a 90/10 ratio for our 850 FP and 650 FP garments. This means that the filling in these products contains 90% down and 10% feathers. This composition guarantees a great insulating capacity and an optimal balance between loft and compression. For lightweight garments, this composition is the most functional: it allows a high amount of downfilling (over 100 grams) while maintaining the loft properties within each panel.

In the case of the Nebulae 850 FP Hydro Repellent Down Jacket, is an ultralight garment that offers maximum insulating capacity at minimal weight, we use a 95/5 composition. Our supplier DownTekTM uses the USA-2000 standard: this certification, rather than establishing an exact composition, reflects a minimum percentage; in practice, 95/5 usually indicates an even higher down composition.

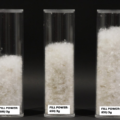

Color

In down with a quality above 650 Cuins (CUbic inches), it is common to mix feathers of different shades, from pure white to gray or even brown. The color is not an indicator of the quality of the down but does give us a reference of its origin. Having feathers of different colors in garments is completely normal as there are different species and breeds of animals, and each individual has its own shades.

The most popular varieties of downfilling are mainly duck down and goose down, which are divided into four varieties: white goose down, white duck down, gray goose/duck down, and gray duck down. There is no difference in terms of fill power and comfort between gray and white down.

From a purely aesthetic standpoint, white feathers are usually used for garments made with light fabrics and gray-brown feathers for dark fabrics. At OS2O, we are committed to environmental sustainability by not using bleach to whiten and not overproduce, making the most of all natural resources and raw materials. Therefore, our garments with down filling include both light and dark colors regardless of the fabric color. This way, we can make the most efficient use of all the down with minimal waste.

Deja una respuesta