By Oswaldo Rivera,

Feather, thanks to the volume of air it creates, is the material that offers the highest insulation-to-weight ratio. For this reason, it has long been used in the development of insulating mountain clothing. Throughout history there have been multiple configurations of down jackets and, although the filling is the same, it is other technical details that most influence its performance. In this post, we’ll look at which ones.

This time we present a technical guide to our high-quality 850 Fill Power down jackets. The challenge of designing and developing high-performance insulating garments begins with identifying the needs to be met. In the case of down-filled jackets, thermal regulation and protection against heat loss are the basis for the development of each product, because as we have seen above, there are a number of situations in which heat is lost. In this sense, in order to achieve the maximum balance between the heat produced by the activity being carried out and the heat loss due to interaction with the environment, the materials and technical configuration of the jackets must be carefully chosen.

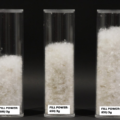

Within our catalog of products with high-quality 850 FP feather fill, we have developed two garments, each for a specific context, and although both have the same feather quality expressed in Fill Power (hereinafter FP), the thermal properties are not the same. The following sections show a comparison of the properties of the Nebulæ 850 FP Hydro Repellent Jacket (woman’s version). and the Turbulence 850 FP Down Jacket (woman’s version) with the aim of deciding what could be the most suitable product for each use.

RECOMMENDED USE – THERMAL CAPACITY – WEIGHT – PADDING – CONFIGURATION

The functionality of any thermal garment is to provide the maximum balance between heat produced and heat loss through environmental interaction. Thermal insulation can be measured with a parameter called indument index, and its unit is expressed in CLO (technically defined as 1 CLO = 0.155 K-m2-W-1). The thermal capacity of the Turbulence 850 FP Down Jacket is 3.82 CLO, which is higher than that of the Nebulæ 850 FP Hydro Repellent Jacket at 2.26 CLO. However, it is also necessary to consider the recommended use and total weight of each garment. In this regard, considering the Nebulæ 850 FP Hydro Repellent Jacket‘s weight of 250 grams, which is much lighter than the vast majority of second-layer garments currently available, the thermal capacity to weight ratio of 9.0 makes the Nebulæ 850 FP an unrivaled product on the market.

FAST&LIGHT activities are characterized by continuous movement, i.e. constant work/heat output. Therefore, the design of a garment specifically for these activities must take into account the intensity of the task and, within its performance, the heat produced must be less than the heat lost. This characteristic has been taken into account when designing the Nebulæ 850 FP Hydro Repellent Jacket, which uses hydro-repellent down, which in addition to protecting against humidity from the outside, prevents sweat saturation produced by work from soaking the down, reducing its capacity to swell (trapping and maintaining warm air).

On the other hand, in technical alpine activities where the intensity and heat produced is lower, a garment that offers greater protection and whose main function is to maintain the heat produced above all else is necessary. In this sense, the Turbulence 850 FP Down Jacket can be considered a meeting garment, ideal for use in the most adverse weather conditions.

In this way, choosing the right garment for the activity you are going to do is key to obtain the best performance. Thus, a garment such as the Nebulæ 850 FP worn on a technical ascent at low intensity will only be efficient if the weather conditions allow for a balance between heat produced and heat lost. Similarly, using the Turbulence 850 FP Down Jacket to tackle a high-intensity ascent will only be efficient if the environmental conditions are so adverse that even producing a large amount of heat is not enough.

In terms of configuration, the difference between the two down jackets is obvious. 100% FAST&LIGHT jackets such as the Nebulæ 850 FP have been developed to offer the essentials (its two pockets are more than enough to carry the essentials), always considering constant movement. On the other hand, a meeting garment such as the Turbulence 850 FP Down Jacket needs to offer more robustness and a series of elements that allow the transport of all the technical tools with its eight pockets. In both cases, the fundamental objective is for the jackets to maintain temperature equilibrium.

FABRIC – FILLING – TREATMENT – CONSTRUCTION – CONFIGURATION

In addition to a high-quality 850 FP feather always with a down percentage above 90, the use of the correct fabric is key. Nylon is a fiber that offers a high resistance capacity in relation to its total weight. In addition, it offers a high windproof capacity, as it is woven very tightly (thanks to its strength) and with very low heat conduction.

At OS2O, in order to achieve the minimum weight of the garment, but without compromising its resistance, we use fabrics with different densities, always under the FAST&LIGHT philosophy. Thus, our fabrics have a maximum linear density of 20D (Deniers) and, in order to offer high resistance, in the case of the Turbulence 850 FP Down Jacket we use a triple fabric wall construction to protect the feather filling. In contrast, for the Nebulæ 850 FP we use one of the lightest and most functional fabrics on the market (developed by the Japanese brand Toray® of 10D micro ripstop and 100% windproof) which allows us to offer a down filling of 100 grams in a jacket that weighs 250 grams in total. Such a lightweight fabric has to be used in a corresponding configuration (two pockets). In other words, overloading it with too many pockets and seams would compromise the structure of the fabric and, if it were to tear, all thermal efficiency of the garment would be lost.

The construction of the individual partitions is a critical part of the garment’s performance. Thus, with 5-centimeter partitions, we can concentrate the down in a smaller area. In this sense, knowing that the function of the feather is to trap warm air, the smaller these partitions are, the more compact the feather will remain, distributing the filling in a very balanced way. Therefore, when using 10-centimeter wide partitions, it is necessary to increase the amount of feathers to have the same balance.

If it is so good, why not put more?

It is the balance between feather quality (swell capacity), fill quantity (in grams), bulkhead construction (in centimeters), and fabric (in deniers) that shapes the high performance of a thermal garment. The Nebulæ 850 FP uses 850 FP down in a 100-gram fill on 5-centimeter partitions, which allows us to have a very compressible garment on a 10-denier fabric. On the other hand, increasing the filling, for example from 100 to 160 grams, could be a big mistake for 3 reasons: 1) using a 5-centimeter septum with such a large amount of feather would compromise its correct inflation as saturating the septum with a feather would have an adverse effect: it would not be able to trap warm air and it would therefore be inefficient to use a feather of such quality; 2) the compression capacity of the jacket would be considerably reduced; and finally, 3) this increase in filling from 100 to 160 grams in a 10 denier fabric would end up causing the down filaments to come out through the seams due to the pressure exerted on the walls of the septum. In short: more is not always better.

In the case of the Turbulence 850 FP Down Jacket, the balance of down-related properties are as follows: 160 grams of filler is used, distributed over a 10 cm wide septum, in a 20 denier fabric, to protect the down from becoming damp due to perspiration. At the same time, as we use a fairly light fabric, we add an extra layer of fabric on the inside of the garment. As the surface area of the septum is larger and the amount of filling is greater, the garment is less compressible. However, it is the swelling of the down when the jacket is worn that is most important, not the compression in transport.

As we have detailed, it is the interaction of the individual elements of a garment and the intended use that will determine the correct choice and thus the performance of the garment. With this information, we hope that you will be able to decide with greater rigor which garment is best suited to what you are looking for.

Deja una respuesta